California Chimney & Fireplace Repair

Looking for a California chimney sweep and fireplace repair service that's regulation-compliant, safety-first, and transparent. We maintain to NFPA 211 with HEPA containment, clear out creosote, verify dampers, and log everything with photos. Our professional inspections, masonry repairs, and UL-listed liner upgrades improve draft, protect against water intrusion, and satisfy California Mechanical and Fire Codes. We also commission inserts, address draft/odor issues, and provide flat-rate scopes with permits when required. Read on to see pricing information, services offered, and coverage zones.

Key Takeaways

- Professional chimney cleaning following CSIA/NFPA 211 standards, including professional creosote cleaning, featuring HEPA-controlled environment and complete Level I-III evaluation featuring detailed photo reports and structured repair planning.

- Code compliance and safety measures: comprehensive checks for California Mechanical, Building, and Fire Codes, CO monitoring and testing, required permits, and clear, itemized billing with no surprise fees.

- Masonry restoration and moisture control: specializing in chimney crowns, caps, flashing installation, tuckpointing work, historical mortar restoration, and moisture-resistant sealants.

- Flue liner installation and enhancement: UL-listed stainless liners with heat barrier, combustion and draft optimization, advanced control systems, fireplace inserts, and wildlife-proof vent covers.

- We offer comprehensive coverage across the Greater LA area, Orange County, Inland Empire, and portions of Ventura and San Diego Counties, offering online scheduling, emergency triage, and seasonal availability.

Expert Chimney Maintenance Services

It's important to regularly schedule chimney cleaning to keep your system safe, efficient, and up to code. This reduces the risk of fires, optimize draft efficiency, and shield nearby building components from corrosive accumulation. Trained professionals utilize appropriately sized brushes to clean flue liners, carefully collect debris at the base, and record inspection findings. Specialized creosote removal techniques handle crystallized and loose accumulation using suitable rotary or chemical treatments while preserving various liner materials including clay, metal, and cast-in-place systems.

The team removes smoke shelves, firebox walls, and connectors, then vacuum with HEPA filtration to manage debris. Crews verify damper performance, eliminate obstacles, and install protective caps to prevent moisture and pest access while ensuring optimal air movement. The service includes advice about proper burning techniques and fuel moisture to reduce deposit accumulation between cleanings, prolonging system longevity and preserving dependable function.

Safety Inspections and Code Compliance

Make sure to get yearly chimney inspections to assess structural integrity, venting, and clearances per NFPA 211. We carefully note problems and inspect connectors and test draft to make sure your system complies with California Building and Fire Code requirements. Based on our thorough inspection report, you can plan essential maintenance and maintain safe, legal operation.

Regular Chimney Safety Evaluations

Many homeowners overlook yearly chimney inspections, which are essential safety precautions that evaluate your system's condition, clearances, and code compliance before the cold season starts. It's important to arrange a Level 1 inspection annually, or Level 2 after any appliance change, relining, or real estate transfer. A certified technician will assess accessible components, confirm proper flue sizing, examine vent terminations, evaluate masonry or metal integrity, and record problems that raise the risk of fire or carbon monoxide exposure.

When scheduling your inspection, make sure to coordinate the visit with your chimney maintenance plan: sweep first if creosote accumulation surpasses Stage 1, then perform video scanning where required. The specialist will examine connection points, smoke chamber junctions, damper operation, and combustible clearances. You'll be provided with a complete written report containing priority maintenance items, photographic evidence, and maintenance scheduling recommendations.

Local Code Compliance

With inspection findings in hand, make sure repairs and maintenance meet building, fire, and mechanical regulations to keep the system legal and safe to operate. Make sure combustible clearances, hearth specifications, and chimney heights meet current standards. If replacing liners, caps, or dampers, verify certified materials are appropriate for the specific appliance and venting requirements.

Make sure to verify permit requirements with your local jurisdiction before initiating the project; numerous municipalities mandate permits for liner installation, rebuilding crowns, installing gas logs, or changing vent routes. Check setback requirements for exterior endpoints, spark arrestors, and roof penetrations, particularly close to property boundaries and adjacent structures. Ensure necessary seismic bracing, anchorage, and spark containment. Log the project with images, materials, and test reports. Book final inspections, fix any issues quickly, and preserve records for insurance requirements and real estate disclosures.

Masonry Repair & Restoration Solutions

You'll tackle typical masonry problems-including spalling brick, cracked crowns, failed mortar joints, and missing flue tiles-utilizing ASTM-approved materials and implementing NFPA 211 guidelines. We'll implement correct repointing with Type N or O mortar for historic brick to minimize damage from too rigid materials. You'll restore structural strength and weather resistance while maintaining existing appearance check here and meeting local California building codes.

Typical Masonry Concerns

Signs of masonry distress include cracks, spalling, and loose mortar that show serious chimney issues affecting safety and building code compliance. It's essential to arrange a Level I or II inspection to assess damage, water intrusion, and thermal stress patterns. Conduct a thorough mortar evaluation to determine bond integrity, joint condition, and material compatibility before starting repointing. First address water intrusion concerns: fix damaged flashing, chimney cap, and crown; then proceed with targeted tuckpointing using ASTM-standard mortar. It's vital to eliminate efflorescence: dry-brush surface salts, improve drainage, and don't use acidic cleaners that can damage brickwork and metal fixtures.

Examine flue offsets, masonry cracks, and firebox separations; these can leak heat and flue gases, not complying with NFPA 211. Swap out compromised masonry, reposition unstable components, and treat porous masonry with vapor-permeable siloxane. Finish with chamber parging and an approved chimney cap.

Traditional Brick Restoration

To begin proper historic brick restoration, address structural and moisture problems. Start by conducting a detailed condition assessment: map out spalls, efflorescence, and displacement, then assess foundation, firebox, and chimney stack stability. Next, carefully match matching units and period-appropriate mortar using microscopic examination and ASTM C270 standards, avoiding mortar with high Portland cement ratios that could deteriorate soft brick. Hand-rake the joints meticulously, reconstruct historical joint patterns, and properly position arched lintels with correct bearing, rust-resistant anchors, and shims. Replace damaged bricks only when necessary with appropriate replacement units. Add through-wall flashing, drip edges, and vapor-permeable sealants. Confirm appropriate spacing to combustibles as specified in NFPA 211, repair caps and crowns, and incorporate weeps. Record all restoration steps and setting periods for regulatory review.

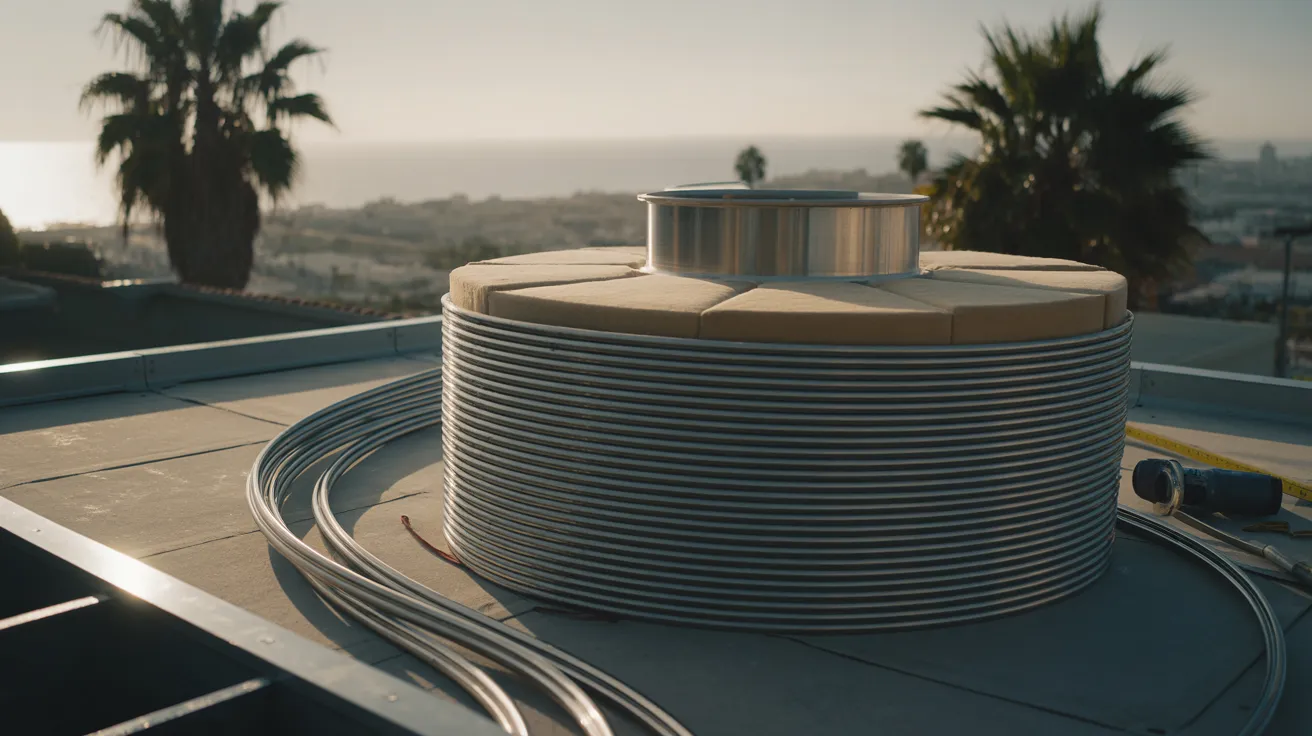

Upgrading and Replacing Your Chimney Liner

Although liners are typically hidden, they are vital in fire safety, draft performance, and code compliance. If your chimney flue shows cracks, is too large, or isn't listed for your appliance, we can provide a code-compliant relining solution. Our UL-listed stainless steel liners are installed meeting NFPA 211 and manufacturer specifications, guaranteeing correct venting and decreasing creosote buildup. We complete the installation with thermal insulation—either poured or wrapped—to establish correct spacing to combustibles, enhance airflow stability, and shield your masonry from corrosive acidic condensates.

We assess materials, spacing, and vertical height, then use camera inspection to check for issues and verify standards. We replace deteriorated clay tiles, adjust improperly aligned connections, and add insulated thimbles and connector boots. Additionally, we seal crown surfaces and complete with a certified cap and storm collar to stop water penetration and animal access, preserving safety and performance.

Modern Fireplace Solutions for Enhanced Efficiency

When you're ready to upgrade your hearth, we emphasize safety-focused improvements that boost safety, efficiency, and functionality. We review appliance listing, venting compatibility, and clearance to combustibles, then specify certified components and necessary permits following California Building Code and local authority guidelines.

You can enhance performance with sealed, high-efficiency inserts sized to your flue and room load, delivering higher AFUE and decreased emissions. We professionally fit stainless steel insulated liners, outside combustion air kits, and low-leakage glass doors to maintain consistent burning and decrease heat loss. For accurate regulation, we offer smart thermostat integration with safety-certified gas valves, ECM blowers, and reliable spill and CO monitoring. We verify draft, manifold pressure, and combustion via analyzer, then log installation details, create maintenance schedules, and label shutoff locations for safety.

Resolving Air Flow, Smells, and Smoke Concerns

Before smoke stains or musty odors alert you, evaluate air circulation and combustion efficiency with a comprehensive review of the full exhaust route. Check chimney-to-roof height proportions, safe distances, and outlet positioning per California Mechanical Code and NFPA 211. Confirm damper functionality, flue sizing, and pipe angle. Measure draft with a manometer; correct negative pressure by adding make-up air or balancing HVAC.

Remove deposits and debris; install new warped baffles. Close spaces at the critical areas with approved flashing components. Mount a appropriate cap and mesh guard. Address odor by fixing moisture issues and enhancing air flow; utilize Air purifiers as a supplemental measure, not a alternative for primary repairs. Test CO levels, confirm detectors, and record corrections.

Clear Pricing and Service Details

For complete transparency, we publish pricing based on defined scopes and specific services and regulatory requirements. We provide fixed price quotes following NFPA 211 standards and California Mechanical Code requirements, rather than unclear estimates. We clearly outline each step: thorough inspection protocols, soot and creosote removal, smoke chamber parging, cap or crown repair, liner evaluation, and security enhancements.

We begin with a detailed documentation and inspection, photo evidence, and a written scope that details compliance standards, materials, and labor costs. You authorize the service only after evaluating the scope. During service, technicians adhere to manufacturer specifications and obtain necessary permits. Upon finishing, you receive comprehensive invoices that correspond to the approved scope, as well as a findings report with before/after images, safety clearance documentation, and maintenance recommendations. No hidden fees, no upsells-just verified, regulation-adherent solutions.

Coverage Areas and Appointment Information

You've seen the way our transparent pricing and compliance-focused processes work, here's how to schedule our services. Our service area includes Los Angeles, Orange County, Inland Empire, and portions of Ventura and San Diego areas. Verify service in your area with your ZIP code and local compliance requirements and HOA guidelines. We provide on-site service visits with professional crews, safety-certified vehicles, and HEPA-standard protection.

Book your appointment online or schedule by phone. You can choose the inspection level (CSIA Level I-III), additional services, and convenient time slots. Scheduling options change with seasonal factors like burn bans and air-quality advisories; winter slots book up fast, so reserve early. We'll send pre-arrival safety information, insurance verification, and technician certifications. You can expect a detailed scope, NFPA 211 compliance report, and permitting details. Emergency situations receive priority within code requirements and access restrictions.

Common Questions

Do You Offer Emergency Chimney Services Outside Regular Business Hours?

Absolutely, we provide emergency chimney services beyond standard operating times. We maintain 24/7 availability with quick after hours assistance for chimney fires, flue blockages, carbon monoxide risks, and structural hazards. You'll reach a certified technician who follows NFPA 211 and IRC guidance, carries out ventilation checks, logs clearances, and isolates unsafe appliances. We stabilize conditions, minimize draft and creosote hazards, and plan compliant follow-up repairs. Contact us right away if you detect gas, smoke, or soot.

Do You Handle Historic Landmark Properties and Preservation Guidelines?

Your historic landmark restoration project is feasible. You can expect period accurate restorations aligned with local, state, and Secretary of the Interior Standards. Our team selects heritage compliant materials, ensure compatibility with existing masonry, and detail methods for preservation boards. We manage permits, prepare shop drawings, and conduct non-invasive inspections. Our technicians comply with NFPA 211 and IRC/IMC requirements, ensure fire-safety clearances, and integrate concealed liners or dampers without affecting character-defining features. You'll receive compliance reports and warranties.

What Certifications and Insurance Do Our Technicians Carry?

Our technicians maintain industry-recognized certifications, including North American Technician Excellence certification for HVAC-related venting and CSIA or similar chimney certifications. They keep up-to-date on OSHA training requirements and adhere to NFPA 211 guidelines and municipal regulations. Your peace of mind is ensured with comprehensive liability insurance and workers' compensation coverage. Our team members carefully document permits, conduct PPE-compliant site work, and deliver detailed inspection reports with visual evidence. They also participate in annual continuing education to maintain active certifications and guarantee code-compliant, safety-oriented service.

Do You Offer Maintenance Plans or Annual Service Memberships?

You have the option to enroll in preventive maintenance packages and membership options that provide annual system evaluations, NFPA 211-compliant cleanings, and priority maintenance booking. We provide comprehensive safety inspections, airflow and burn efficiency checks, and code-compliant recommendations for system elements and required spacing. Our service features camera inspections as needed, alert you before cold weather arrives, and lock in special rates. Maintenance programs decrease harmful deposits, CO dangers, and chimney wear, supporting your warranty and insurance specifications.

Is My Fireplace Compatible with Eco-Friendly, Low-Smoke Fuels

Indeed - provided your unit is rated for alternative fuel use. Similar to fine-tuning an instrument, you need to pair the correct fuel with your appliance. Always check the manual and UL/ANSI certification for wood pellets or biofuel alternatives. Pellet stoves need proper hoppers, augers, and venting that meet ASTM/UL standards; traditional fireplaces generally cannot safely burn pellets. Confirm that draft levels, CO monitors, and safety clearances meet code specifications. If approved, utilize low-ash fuels, maintain dry storage, and schedule yearly inspections for safe, clean operation.

Final Thoughts

As flames subside to a consistent glow, you'll feel the peace of mind of a code-compliant, well-maintained system. Your ventilation performs optimally, liners sealed tight, masonry set plumb and sound. Zero smoke leakage, no unwanted air flow-just effective, consistent heat. From NFPA-211 inspections to expert maintenance, every process follows best practices and local codes. You get clear pricing, scheduled on your terms, and detailed reporting. Rest assured, fire safe, and benefit from a fireplace that delivers dependable warmth.